My Store

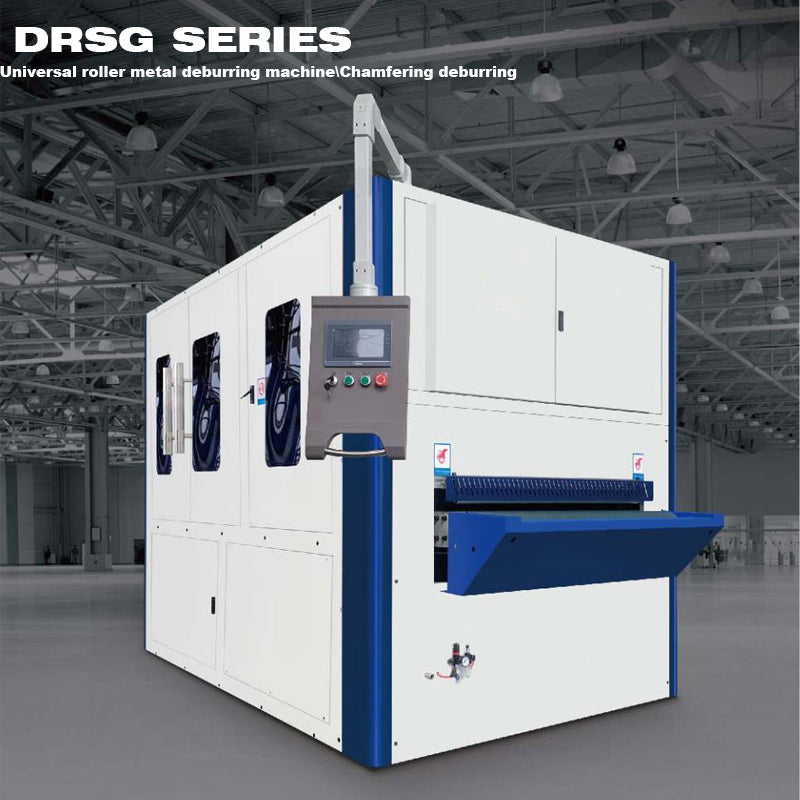

Sheet Metal Brushing Deburring Machine for Laser Cutting Plasma Cutting Parts Edge Polishing

Sheet Metal Brushing Deburring Machine for Laser Cutting Plasma Cutting Parts Edge Polishing

Couldn't load pickup availability

Product function introduction:

Abrasive belt: The abrasive belt rotates at high speed driven by the grinding roller to draw, polish and remove slag from the surface of the workpiece.

Universal roller: Thousand-wire wheel abrasive rotates (rotates) at high speed and revolves 360° to polish the 90° edge of the workpiece, making the contour edges around the surface of the workpiece and in the hole smooth and rounded, producing a rounded effect.

The equipment is used for: surface drawing, polishing, scratch removal, deburring, and obtuse angle of laser cutting parts, stamping parts, water jet cutting, plasma cutting parts, and flame cutting parts.

Basic technical parameters of equipment:

Processing width: 600mm 800mm 1000mm 1300mm 1600mm

Processing thickness: 0.5-100mm

Feeding table adsorption method: strong permanent magnet adsorption (workpiece size ≥ 20 × 20), vacuum adsorption (workpiece size ≥ 50 × 50), semi-magnetic and semi-vacuum adsorption.

Automatic thickness setting device: four-column connecting rod lifts synchronously, lifting servo motor lift accuracy ±0.01mm

Processing speed: Conveying speed: 0.3m-9m/min (adjustable with variable frequency), Thousand-wire wheel speed 5m/s-20m/s (adjustable with variable frequency)

PLC control of the whole machine and touch screen adjustment parameters

Equipped with a wet industrial dust collector or pulse flame-retardant dust collector to process dust to achieve safe and environmentally friendly production.

Share