My Store

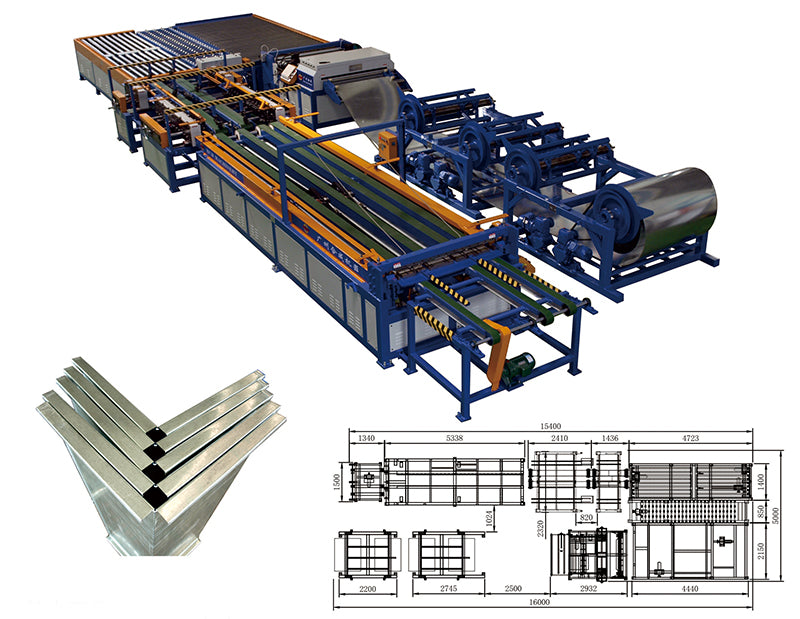

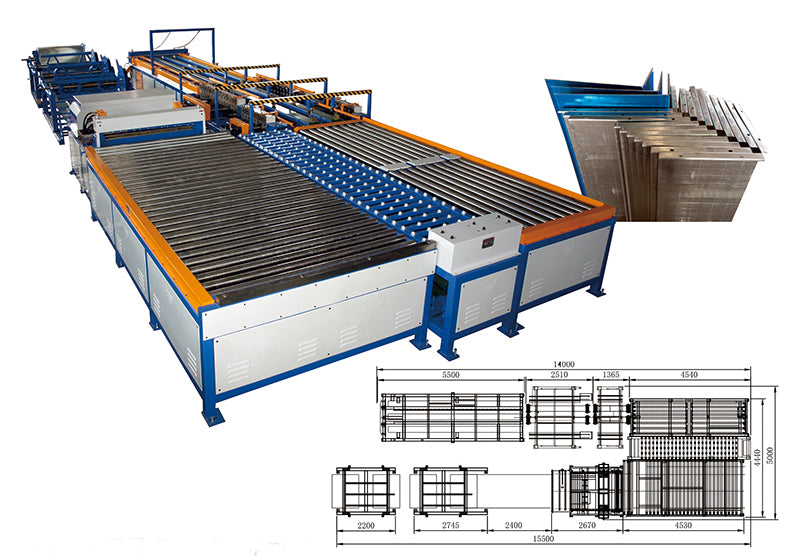

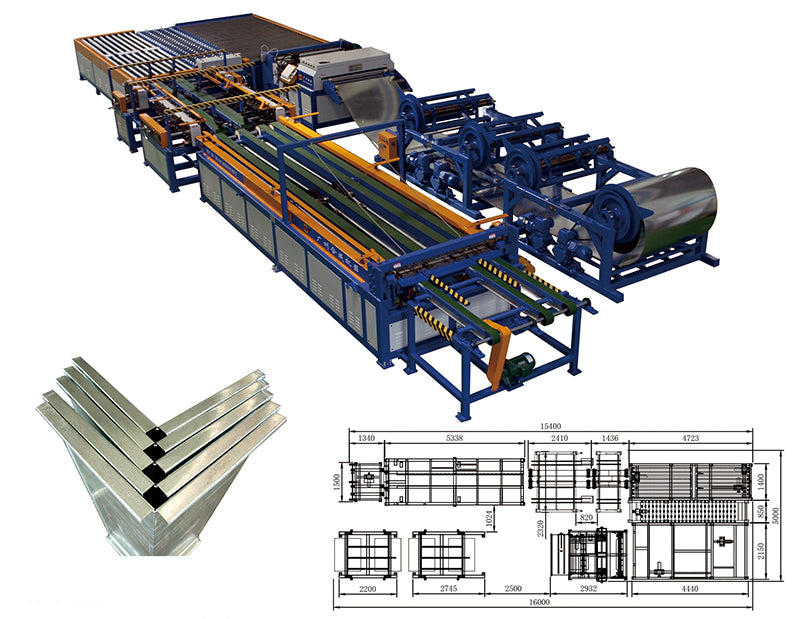

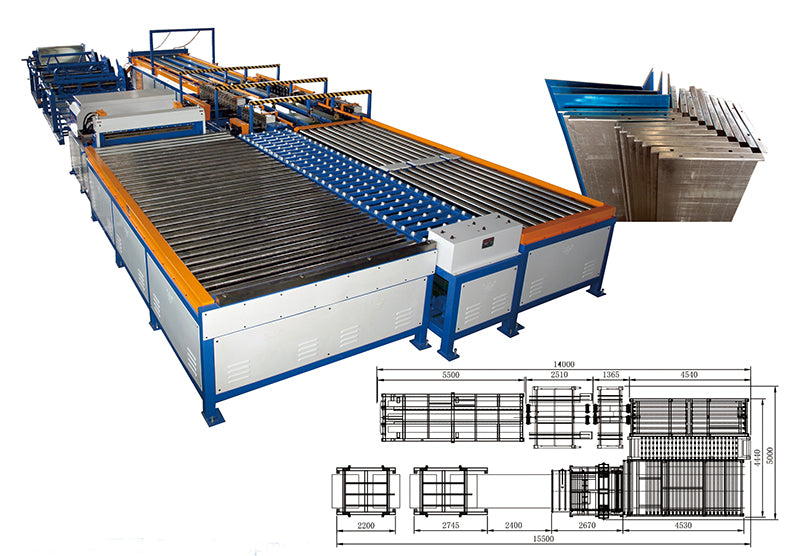

Air duct production U-shaped six lines

Air duct production U-shaped six lines

Couldn't load pickup availability

Technical parameters of U-shaped six lines for air duct production

The U-shaped six-line production line for air ducts is composed of a loading rack, a main machine (leveling and pressing ribs, hydraulic punching point and square punching, support hole flange hole punching, hydraulic shearing machine), conveyor platform 1, combined angle bite device, and conveyor Platform 2, dual-machine linkage common plate flange machine and dual-linkage bite machine, servo manipulator grabbing and feeding platform, TDF hydraulic folding machine. The electrical control part adopts full computer control, bending servo feeding and accurate positioning. The maximum feeding speed is 16m/min, and the length error is ±0.5mm. This line can process TDF common plate flange and angle iron flange air ducts, and the replacement is simple and fast.

basic configuration:

- One set of material rack (including four material cores)

- Main machine (including leveling, bead pressing, punching, punching, breaking, computer operating system)

- Conveyor platform 1

- Combined angle bite device

- Conveyor platform 2

- Dual-machine linkage common plate flange machine

- Double linkage bite machine

- Overall conveying and folding device

working principle

- Unwinding, leveling and cutting

- Uncoiling, leveling, beading, punching, square punching, punching

- Breaking and punching Oriental bone

- Bilateral common plate flange Bilateral angle iron flange

- Folding and forming

Basic parameters:

Processing plate thickness: 0.5-1.2mm (galvanized plate or low carbon steel plate)

Maximum working speed: 16m/min

Maximum processing plate width: 1250mm

Control error: length ±0.5mm, diagonal ±0.8mm

Loading weight of material rack: ≤8000kg

Total motor power: 38kw

Overall weight: 12 tons

Area size: 16m*5m

Electrical configuration

System plc, display screen: Siemens, Germany

Servo motor: Taiwan Delta

Contactor circuit breaker: CHINT

Hydraulic valve reversing valve: Beijing Huade

Coreless cylinder: Yadeke

Linear guide: Taiwan Wantong

Frequency converter: Taiwan Sifang

Features of this machine:

Linear processing and high production efficiency require at least one operator. The daily processing capacity is 1,500 square meters. You only need to enter the size of the air duct, and the production line automatically completes uncoiling, leveling, beading, punching, punching, shearing, joint bite, common plate flange/angle iron flange forming, and folding. forming.

Share